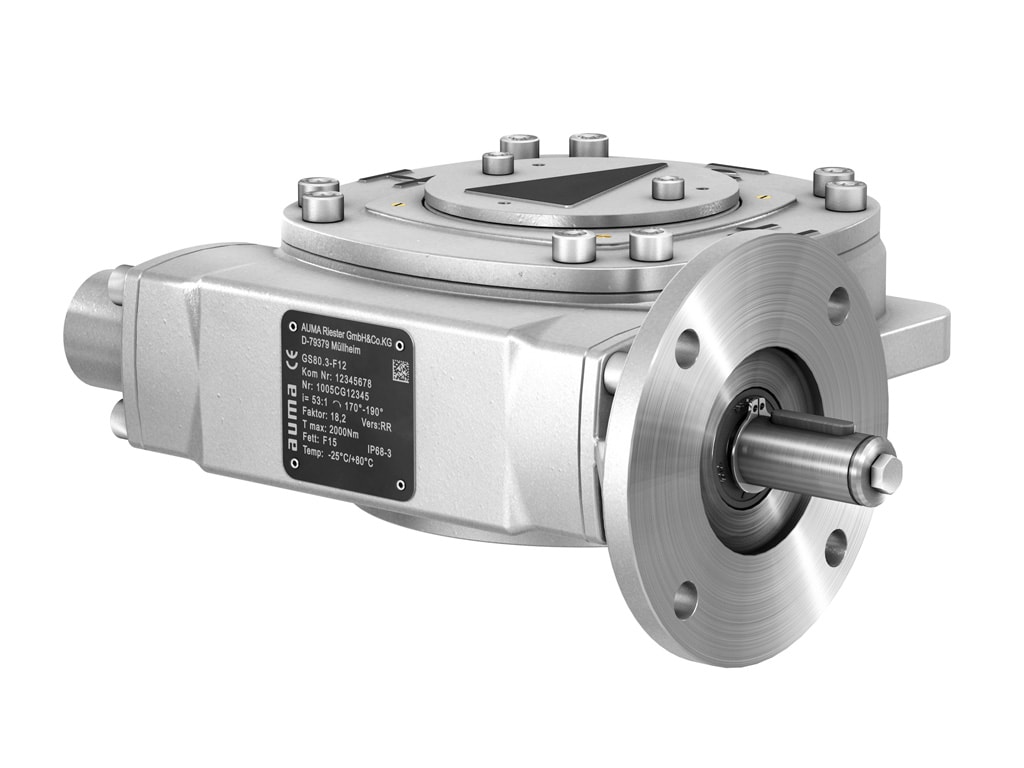

AUMA Part-turn Gearboxes – High-Performance Solutions for Valve Automation

1. Introduction to AUMA Part-turn Gearboxes

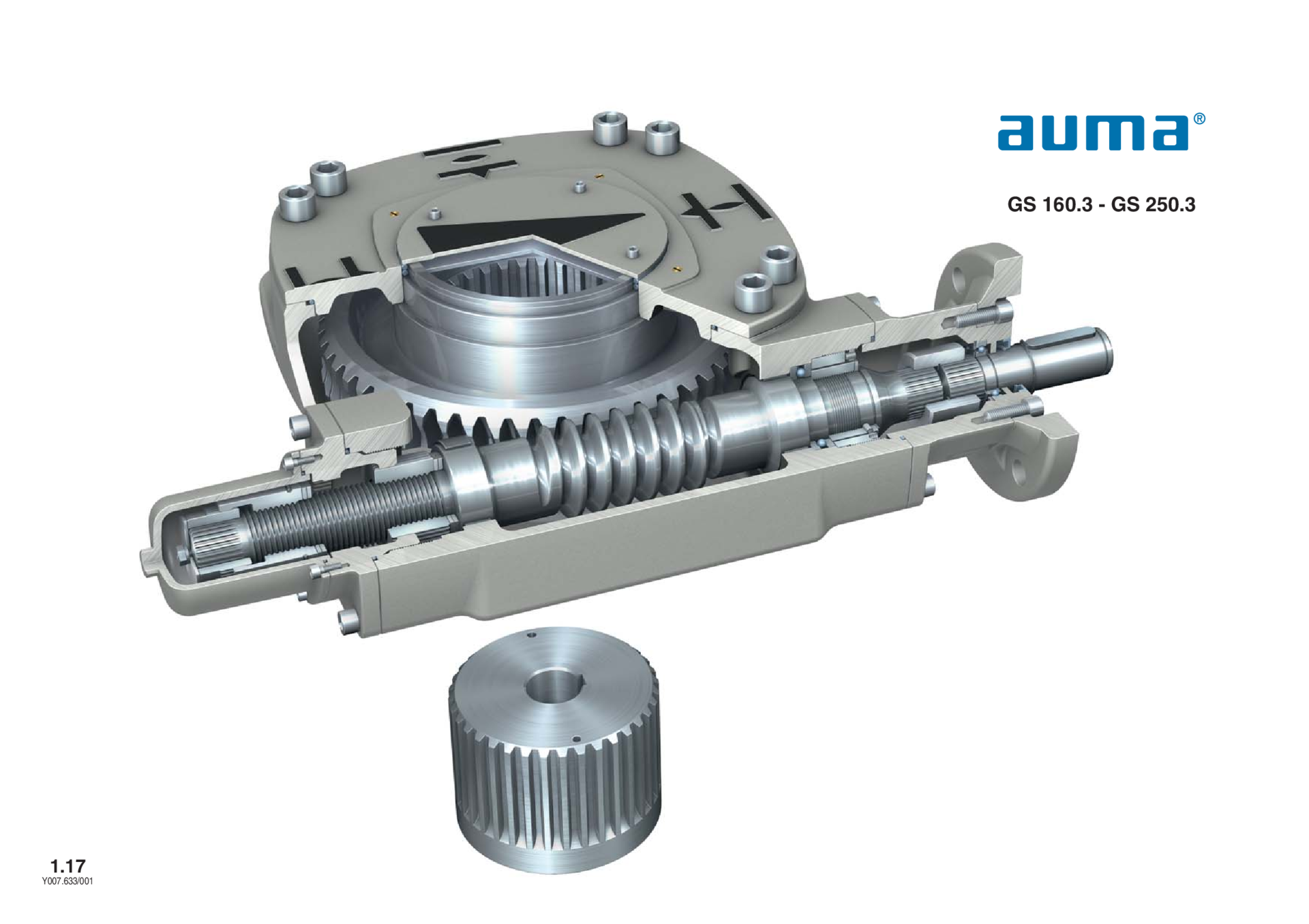

AUMA part-turn gearboxes are designed to convert multi-turn actuator motion into part-turn (quarter-turn) movement, making them ideal for operating butterfly valves, ball valves, dampers, and plug valves. These gearboxes provide high torque transmission, durability, and precise control, ensuring smooth and reliable valve operation in various industries.

2. Key Features of AUMA Part-turn Gearboxes

- High Torque Capacity – Designed to handle demanding industrial applications.

- Robust and Durable Construction – Built for long-term performance in harsh environments.

- Compact and Modular Design – Enables easy integration with AUMA electric actuators and manual operations.

- Manual Override Option – Equipped with a handwheel or lever for emergency operation.

- Weatherproof and Corrosion-resistant – Suitable for outdoor and offshore applications.

- Versatile Mounting Configurations – Compatible with various part-turn valve types.

3. Applications of AUMA Part-turn Gearboxes

- Water and Wastewater Treatment – Used for flow control in pipelines and treatment plants.

- Power Plants – Essential for steam and cooling water valve operation.

- Oil & Gas Industry – Reliable valve control in refineries, pipelines, and offshore rigs.

- Marine and Shipbuilding – Corrosion-resistant solutions for shipboard valve automation.

- Chemical and Pharmaceutical Industries – Designed for aggressive and hazardous environments.

4. Types of AUMA Part-turn Gearboxes

- According to ISO 22109 and ISO 22153, a part-turn gearbox is a gearbox which transmits torque to the valve for less than one revolution and that can be manually operated by handwheel and/or automated with a multi-turn actuator.

- Part-turn gearboxes can be applied wherever a 90° swivel movement is required for the operation of a closing element. GS part-turn gearboxes combined with SA multi-turn actuators act as part-turn actuators.

- Consequently, nominal torques up to 675,000 Nm can be achieved. These combinations complement the SQ type range for part-turn valves. GS are suitable for open-close and modulating duty. Both swing angle > 90° as well as multi-turn applications are possible.

- GHE part-turn gearboxes are used for manual operation of part-turn valves on ships.

- Part-turn gearbox with base and lever offer consequently an ideal solution if valves like butterfly valves can only be operated using a lever arrangement, due to space constraints.

5. Advantages of Using AUMA Part-turn Gearboxes

- Improves Actuator Efficiency – Enhances performance and extends actuator lifespan.

- Reliable and Maintenance-friendly – Designed for long service life with minimal maintenance.

- Flexible Integration – Compatible with AUMA and third-party actuators.

- Safety and Precision – Ensures accurate valve positioning and operational safety.

6. Choosing the Right AUMA Part-turn Gearbox

When selecting an AUMA part-turn gearbox, consider:

- Required torque output and valve specifications.

- Operating environment (corrosive, hazardous, outdoor, underwater).

- Mounting configuration and actuator compatibility.

- Manual or motorized operation preference.