AUMA Multi-turn Actuators – High-Performance Solutions for Industrial Automation

1. Introduction to AUMA Multi-turn Actuators

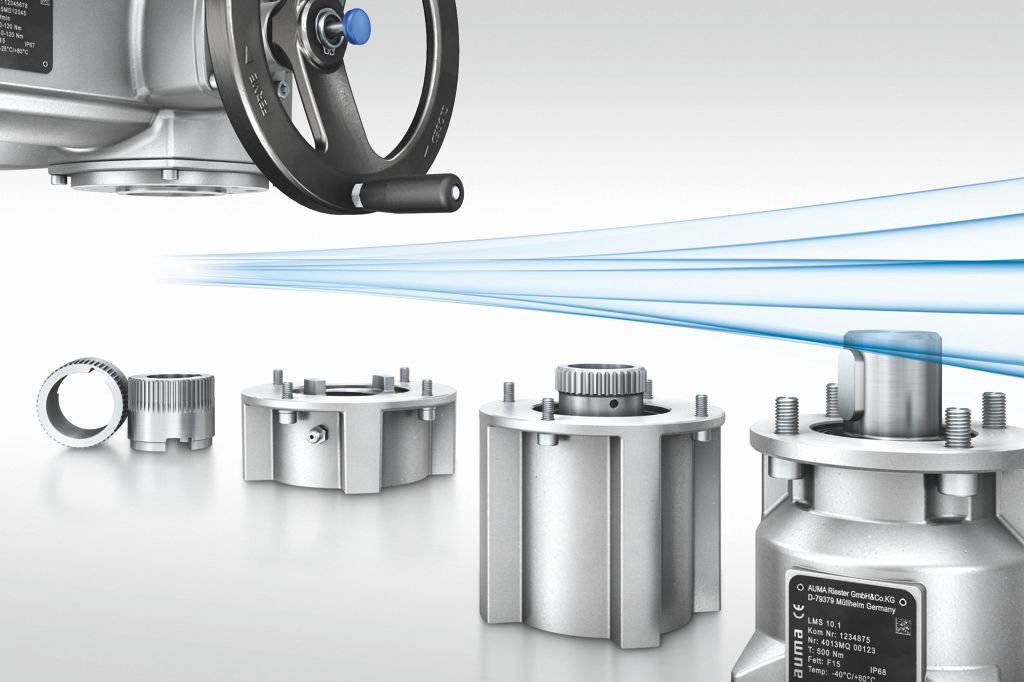

AUMA multi-turn actuators are designed to perform continuous rotational motion, making them ideal for operating gate valves, globe valves, sluice gates, and other linear-motion valves. These actuators provide high precision, torque, and reliability, ensuring smooth valve automation in water treatment, power plants, oil & gas, and process industries.

2. Key Features of AUMA Multi-turn Actuators

- Continuous Rotational Motion – Designed for multi-turn valve applications.

- Wide Torque Range – Handles up to 120,000 Nm for demanding industrial needs.

- Modulating, On/Off, and Positioning Control – Adaptable to various operational requirements.

- Smart Digital Controls – Supports PROFIBUS, Modbus, Industrial Ethernet, and HART for SCADA/DCS integration.

- Manual Override & Safety Features – Equipped with handwheel operation for emergency use.

- Weatherproof & Explosion-proof Models – Designed for harsh environments, including ATEX-certified hazardous areas.

- High Durability & Low Maintenance – Built for long service life with minimal maintenance.

3. Applications of AUMA Multi-turn Actuators

- Water & Wastewater Treatment – Automates gate valves, sluice gates, and pipeline systems.

- Power Plants – Controls steam, cooling water, and fuel supply valves.

- Oil & Gas Industry – Ensures precise operation of valves in refineries, pipelines, and offshore rigs.

- Marine & Shipbuilding – Provides reliable automation for shipboard valves and ballast systems.

- Chemical & Pharmaceutical Industries – Handles aggressive fluids and hazardous environments.

4. Types of AUMA Multi-turn Actuators

1️⃣ SA Series (Standard Multi-turn Actuators)

- Designed for on/off and positioning control.

- Offers torque up to 120,000 Nm.

- Available in weatherproof (IP68) and explosion-proof versions.

2️⃣ SAR Series (Modulating Multi-turn Actuators)

- Designed for continuous modulating duty with high precision.

- Supports high-frequency positioning control for process automation.

- Includes integrated position feedback and smart communication.

3️⃣ SAEx & SAREx Series (Explosion-proof Multi-turn Actuators)

- Certified for hazardous areas (ATEX, IECEx-approved).

- Ensures safe operation in oil, gas, and chemical industries.

4️⃣ Fail-safe Multi-turn Actuators

- Equipped with spring-return or battery-backed solutions for emergency shutdown (ESD).

- Provides reliable operation in critical safety applications.

Open-close (SA)

| Type | Operating time at 50 Hz | Setting range for torque | Maximum number of starts (Starts max) | Valve mounting flange | |

| [rpm] | [Nm] | [1/h] | EN ISO 5210 | DIN 3210 | |

| SA 07.2 | 4 – 180 | 10 – 30 | 60 | F07 or F10 | G0 |

| SA 07.6 | 4 – 180 | 20 – 60 | 60 | F07 or F10 | G0 |

| SA 10.2 | 4 – 180 | 40 – 120 | 60 | F10 | G0 |

| SA 14.2 | 4 – 180 | 100 – 250 | 60 | F14 | G1/2 |

| SA 14.6 | 4 – 180 | 200 – 500 | 60 | F14 | G1/2 |

| SA16.2 | 4 – 180 | 400 – 1,000 | 60 | F16 | G3 |

| SA25.1 | 4 – 90 | 630 – 2,000 | 40 | F25 | G4 |

| SA30.1 | 4 – 90 | 1,250 – 4,000 | 40 | F30 | G5 |

| SA35.1 | 4 – 45 | 2,500 – 8,000 | 30 | F35 | G6 |

| SA40.1 | 4 – 32 | 5,000 – 16,000 | 20 | F40 | G7 |

| SA48.1 | 4 – 16 | 10,000 – 32,000 | 20 | F48 | – |

Multi-turn actuators, Modular allrounders (SAR)

| Type | Operating time at 50 Hz | Setting range for torque | Maximum torque for modulation duty | Maximum number of starts (Starts max) | Valve mounting flange | |

| [rpm] | [Nm] | [Nm] | [1/h] | EN ISO 5210 | DIN 3210 | |

| SAR 07.2 | 4 – 90 | 15 – 30 | 15 | 1,5 | F07 or F10 | G0 |

| SAR 07.6 | 4 – 90 | 30 – 60 | 30 | 1,5 | F07 or F10 | G0 |

| SAR 10.2 | 4 – 90 | 60 – 120 | 60 | 1,5 | F10 | G0 |

| SAR 14.2 | 4 – 90 | 120 – 250 | 120 | 1,2 | F14 | G1/2 |

| SAR 14.6 | 4 – 90 | 250 – 500 | 200 | 1,2 | F14 | G1/2 |

| SAR 16.2 | 4 – 90 | 500 – 1,000 | 400 | 900 | F16 | G3 |

| SAR 25.1 | 4 – 11 | 1,000 – 2,000 | 800 | 300 | F25 | G4 |

| SAR 30.1 | 4 – 11 | 2,000 – 4,000 | 1,6 | 300 | F30 | G5 |

5. Advantages of Using AUMA Multi-turn Actuators

- High Precision & Reliability – Ensures accurate valve positioning and smooth operation.

- Remote & Smart Control Capabilities – Fully compatible with industrial automation networks.

- Rugged Design for Industrial Use – Engineered for demanding environments.

- Flexible Integration with Various Valves – Suitable for multi-turn and linear-motion valves.

- Fail-safe & Redundant Options – Enhances safety in critical applications.

6. Selecting the Right AUMA Multi-turn Actuator

When choosing an AUMA multi-turn actuator, consider:

- Required torque and speed based on valve specifications.

- Control type – On/off, modulating, or fail-safe operation.

- Environmental factors – Weatherproof, underwater, or hazardous area certification.

- Integration with control systems – Compatibility with SCADA, PLC, or DCS.

- Manual vs. automated operation – Need for handwheel override.