AUMA Part-turn Actuators – Reliable Solutions for Industrial Valve Automation

1. Introduction to AUMA Part-turn Actuators

AUMA part-turn actuators are designed for quarter-turn (90°) valve operations, making them ideal for controlling butterfly valves, ball valves, plug valves, and dampers. These actuators ensure precise positioning, high torque output, and long-term reliability, making them a preferred choice for various industrial automation applications.

2. Key Features of AUMA Part-turn Actuators

- Precise Part-turn (90°) Motion – Optimized for quarter-turn valves.

- High Torque Output – Handles demanding applications with torque capacities up to 675,000 Nm.

- Electric, Modulating, and Fail-safe Options – Available for different control requirements.

- Integrated Smart Controls – Supports PROFIBUS, Modbus, Industrial Ethernet, and HART for automation systems.

- Manual Override for Safety – Equipped with handwheel operation for emergencies.

- Weatherproof & Explosion-proof Variants – Suitable for harsh and hazardous environments (ATEX-certified models available).

- Durable and Low Maintenance – Designed for long service life with minimal maintenance needs.

3. Applications of AUMA Part-turn Actuators

- Water & Wastewater Treatment – Controls flow in pipelines, pumps, and filtration systems.

- Power Plants – Regulates steam, cooling water, and fuel supply.

- Oil & Gas Industry – Automates valves in refineries, offshore platforms, and pipelines.

- Marine & Shipbuilding – Controls ballast and fuel systems with corrosion-resistant designs.

- Chemical & Pharmaceutical Industries – Ensures precise flow control in hazardous environments.

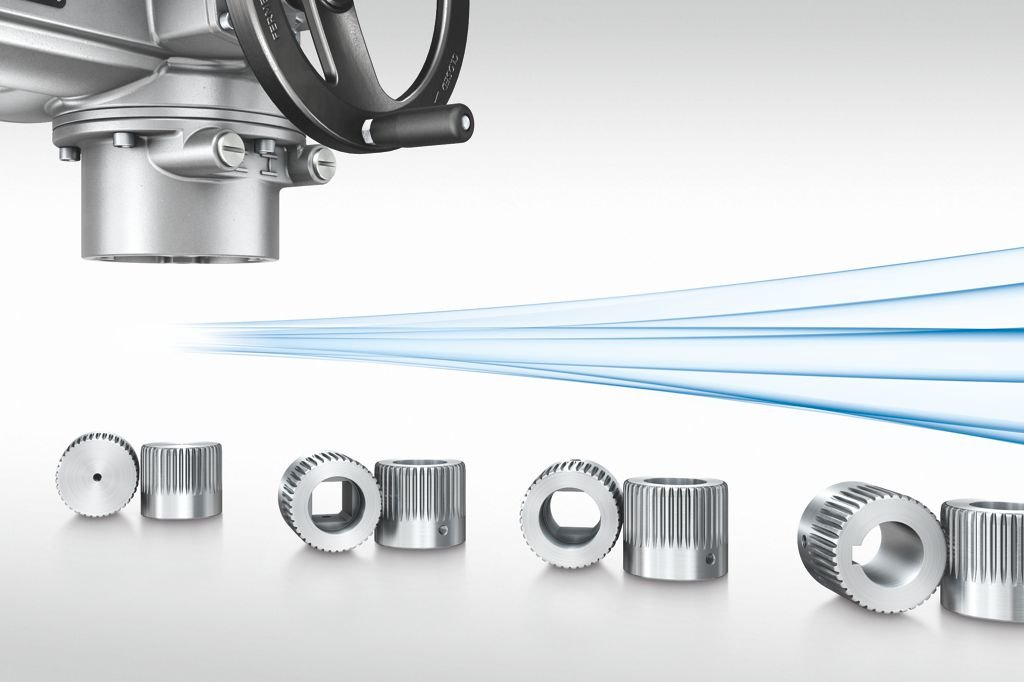

4. Types of AUMA Part-turn Actuators

1️⃣ SG Series (Standard Part-turn Actuators)

- Designed for basic on/off control of quarter-turn valves.

- High torque output for industrial valve automation.

- Available in weatherproof (IP68) and explosion-proof variants.

2️⃣ SQ Series (Modulating Part-turn Actuators)

- Designed for modulating duty with continuous positioning.

- Offers high precision and optimized for process control applications.

- Supports advanced communication protocols (PROFIBUS, Modbus, etc.) for integration with SCADA/DCS.

3️⃣ SQEx Series (Explosion-proof Part-turn Actuators)

- Certified for use in hazardous areas (ATEX, IECEx-approved).

- Ensures safe and reliable valve automation in oil, gas, and chemical industries.

4️⃣ Fail-safe Part-turn Actuators

- Includes spring-return or battery-backed solutions for emergency shutdown (ESD).

- Ensures safe operation in critical safety applications.

Bộ truyền động quay từng phần cho chế độ Open-close (SQ)

| Type | Operating time at 50 Hz | Setting range for torque | Maximum number of starts (Starts max) | Valve mounting flange | |

| [s] | [Nm] | [1/h] | Standard (ISO 5211) | Option (EN ISO 5211) | |

| SQ 05.2 | 4 – 32 | 50 – 150 | 60 | F05/F07 | F07, F10 |

| SQ 07.2 | 4 – 32 | 100 – 300 | 60 | F05/F07 | F07, F10 |

| SQ 10.2 | 8 – 63 | 200 – 600 | 60 | F10 | F12 |

| SQ 12.2 | 16 – 63 | 400 – 1,200 | 60 | F12 | F10, F14, F16 |

| SQ 14.2 | 24 – 100 | 800 – 2,400 | 60 | F14 | F16 |

Bộ truyền động quay từng phần cho chế độ điều biến (SQR)

| Type | Operating time at 50 Hz | Setting range for torque | Maximum torque for modulation duty | Maximum number of starts (Starts max) | Valve mounting flange | |

| [s] | [Nm] | [Nm] | [1/h] | Standard (ISO 5211) | Option (EN ISO 5211) | |

| SQR 05.2 | 8 – 32 | 75 – 150 | 75 | 1,5 | F05/F07 | F07, F10 |

| SQR 07.2 | 8 – 32 | 150 – 300 | 150 | 1,5 | F05/F07 | F07, F10 |

| SQR 10.2 | 11 – 63 | 300 – 600 | 300 | 1,5 | F10 | F12 |

| SQR 12.2 | 16 – 63 | 600 – 1 200 | 600 | 1,5 | F12 | F10, F14, F16 |

| SQR 14.2 | 36 – 100 | 1,200 – 2,400 | 1,2 | 1,5 | F14 | F16 |

5. Advantages of Using AUMA Part-turn Actuators

- Reliable and Precise Valve Control – Ensures smooth and accurate operation.

- Remote and Smart Control Capabilities – Fully compatible with industrial automation networks.

- High Durability and Low Maintenance – Engineered for long operational life.

- Flexible Integration with Different Systems – Works with various valve types and control setups.

- Safety and Redundancy Features – Available with fail-safe and emergency operation options.

6. Selecting the Right AUMA Part-turn Actuator

When choosing an AUMA part-turn actuator, consider:

- Required torque output for the specific valve type.

- Control type – On/off, modulating, or fail-safe operation.

- Environmental conditions – Weatherproof, underwater, or hazardous area use.

- Integration with control systems – Compatibility with SCADA, PLC, or DCS.

- Manual vs. automatic operation – Need for handwheel override.