AUMA Controls – "Intelligent Solutions for Actuator Automation"

1. Introduction to AUMA Controls

AUMA controls are advanced electronic control units designed to enhance the performance, flexibility, and automation of AUMA actuators. These controls provide precise operation, monitoring, and communication capabilities, making them essential for remote valve control and industrial process automation.

AUMA offers a range of intelligent actuator control solutions for multi-turn, part-turn, and linear actuators, enabling seamless integration into modern SCADA, DCS, and PLC systems.

2. Key Features of AUMA Controls

- Precise Valve Control – Supports on/off, modulating, and positioning operations.

- Integrated Monitoring & Diagnostics – Provides real-time feedback on valve status, torque, and operating conditions.

- Fieldbus Communication – Supports PROFIBUS, Modbus, HART, Foundation Fieldbus, and Industrial Ethernet protocols.

- Local & Remote Operation – Allows manual control via a local control interface and remote operation via automation systems.

- Fail-Safe & Redundant Options – Ensures safe operation in critical applications with emergency shutdown (ESD) and fail-safe features.

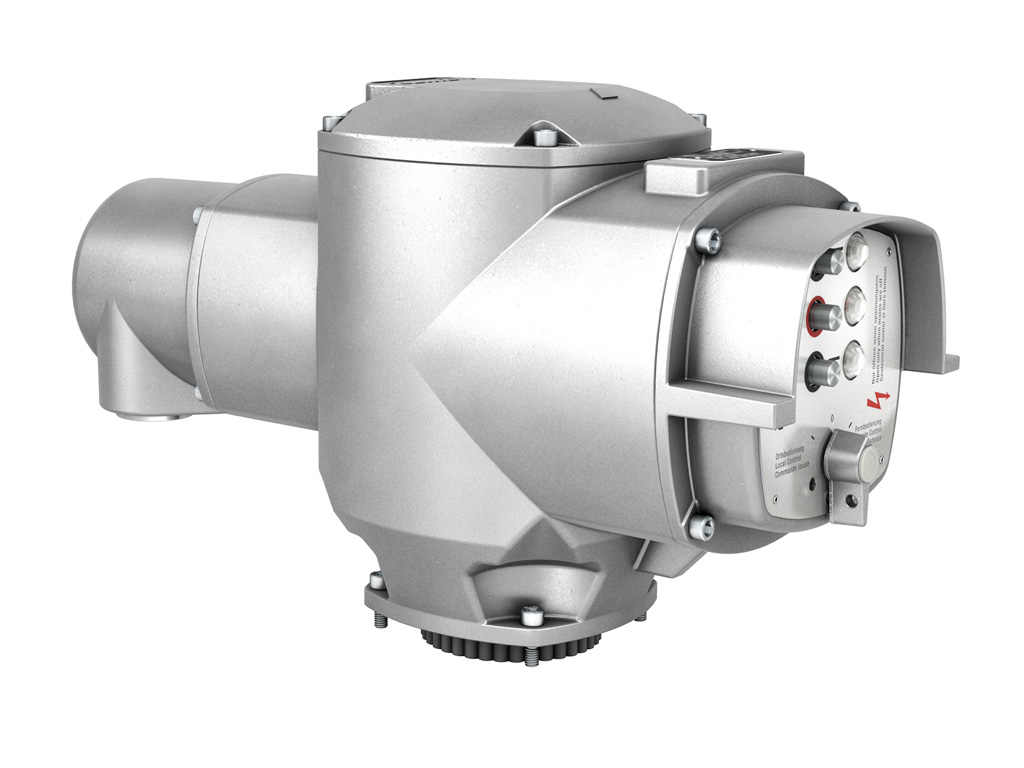

- Weatherproof & Explosion-proof Variants – Designed for harsh environments, including offshore, chemical, and hazardous locations.

- User-friendly Interface – Intuitive LCD display, push buttons, and LED indicators for easy operation and troubleshooting.

3. Applications of AUMA Controls

- Water & Wastewater Treatment – Automates valve operations in water distribution and sewage treatment.

- Power Plants – Used for controlling steam and cooling systems in thermal and nuclear plants.

- Oil & Gas Industry – Provides safe and efficient valve automation for pipelines, refineries, and offshore platforms.

- Marine & Shipbuilding – Controls ballast, cooling, and fuel systems in ships and offshore structures.

- Chemical & Pharmaceutical Industries – Ensures precise flow control in hazardous and corrosive environments.

4. Types of AUMA Controls

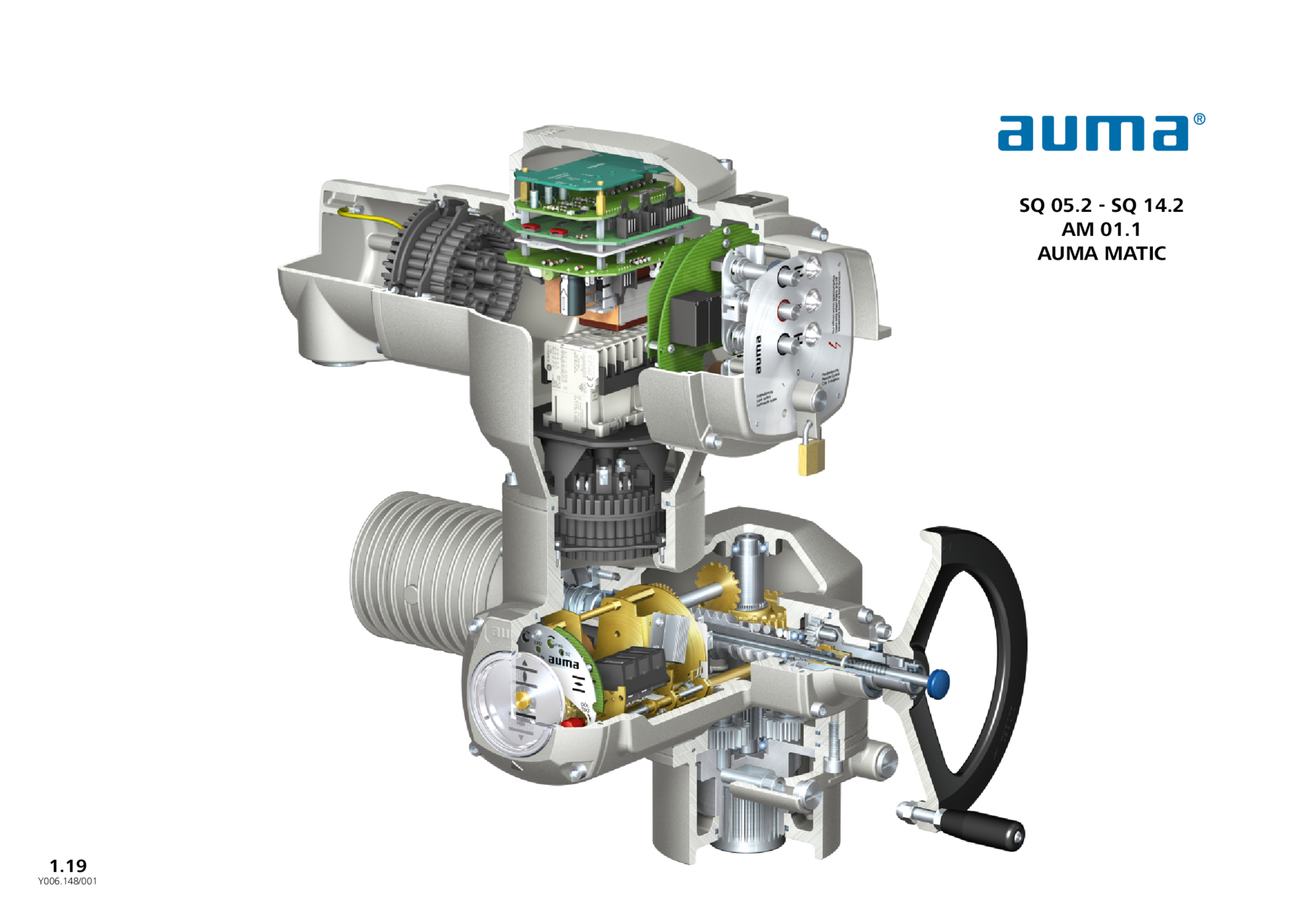

1️⃣ AUMA AM Series (Basic Actuator Controls)

- Provides simple on/off and positioning control for standard valve automation.

- Supports local push-button operation and basic feedback signals.

- Ideal for small-scale applications with limited automation requirements.

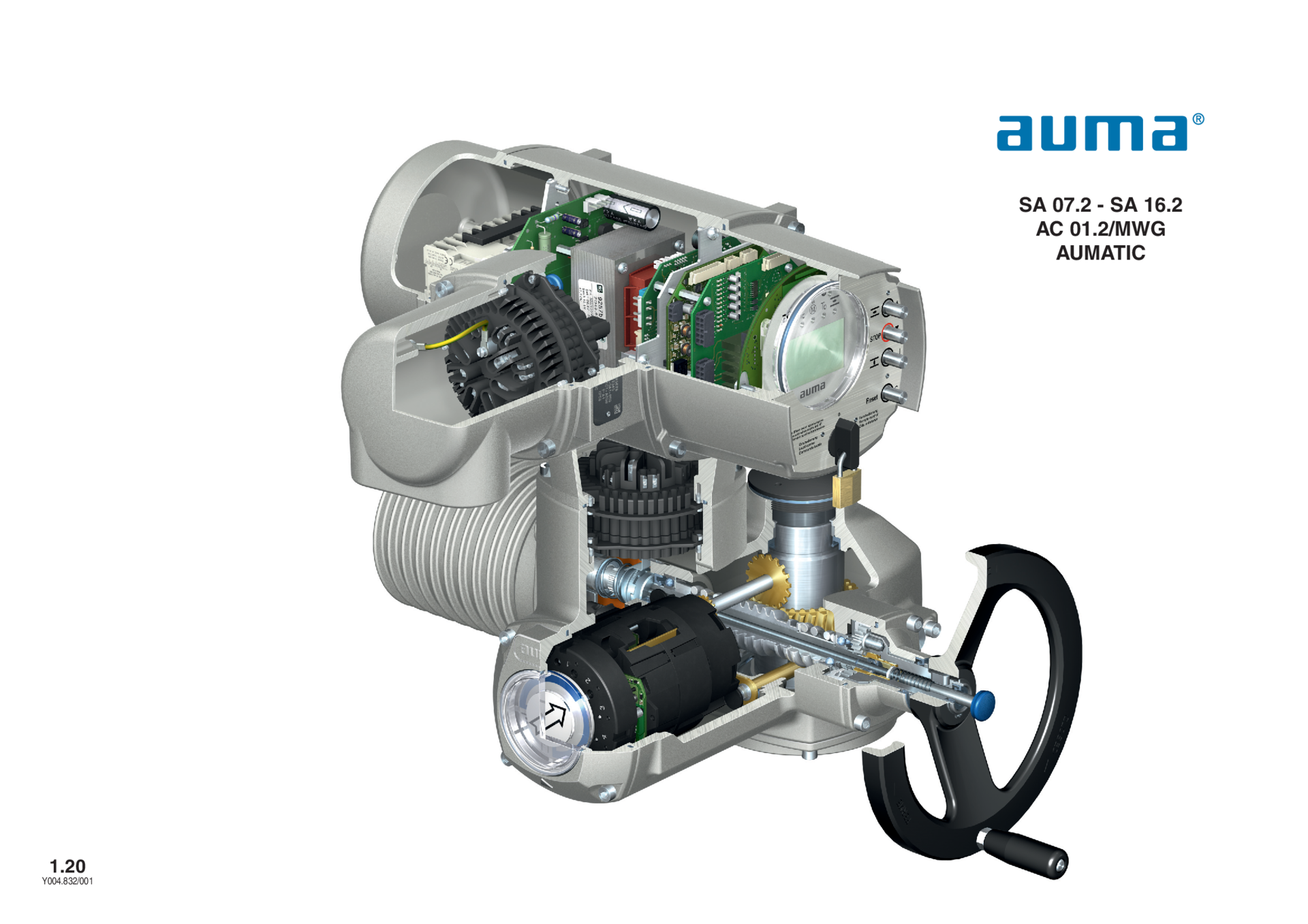

2️⃣ AUMA AC Series (Advanced Controls)

- Includes integrated diagnostics, monitoring, and advanced control algorithms.

- Supports modulating control (continuous positioning) for process automation.

- Offers fieldbus communication (PROFIBUS, Modbus, etc.) for integration with SCADA/DCS.

- Suitable for medium to high-level automation requirements.

3️⃣ AUMA SIMA (Smart Integrated Modular Actuator)

- Fully digital and networked control for high-end automation.

- Supports predictive maintenance, remote diagnostics, and cybersecurity features.

- Provides seamless integration with Industry 4.0 and IIoT (Industrial Internet of Things) solutions.

- Best suited for complex and critical valve automation applications.

5. Advantages of Using AUMA Controls

- Increased Automation & Process Efficiency – Enables remote monitoring and control for optimized operations.

- Reduced Downtime & Maintenance Costs – Predictive diagnostics help prevent failures before they occur.

- Scalable & Flexible Integration – Compatible with both legacy and modern control systems.

- Enhanced Safety & Reliability – Fail-safe and emergency shutdown (ESD) features ensure plant safety.

- Easy Configuration & User-friendly Operation – Simplified setup with graphical LCD displays and intuitive controls.

6. Selecting the Right AUMA Control Unit

When choosing an AUMA control unit, consider:

- Required control type – On/off, modulating, or continuous positioning.

- Communication needs – Fieldbus protocols, industrial Ethernet, or conventional I/O.

- Environmental conditions – Hazardous area classification, IP rating, and corrosion resistance.

- Integration with existing systems – Compatibility with SCADA, PLC, or DCS.

- Safety and redundancy requirements – Need for fail-safe operation or emergency shutdown.