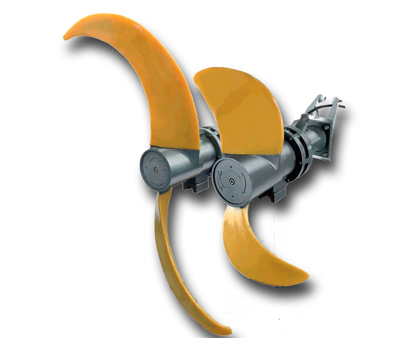

The ACS current accelerator groups consist of a propeller with two blades and an electric motor. It has a reducer, which generates a rotation of the propeller at low revolutions, which increases the physical and energetic performance with respect to other agitation and mixing systems.

They are mainly used in wastewater treatment plants, for applications in nitrification- denitrification ponds, sludge treatment, disinfection and mixing, homogenizing the sludge, as well as the formation of homogeneous flow of liquids in the tanks, for the treatment of this type of water.

The installation of the current accelerators is usually carried out by means of a universal guide system, which allows the use of the agitator in tanks of different water depths, simultaneously avoiding the formation of dead zones.

With the guide tube system, there is no difficulty in lowering the throttle to the reservoir, even if it is flooded.

The reverse operation is just as simple, if the equipment needs to be removed for repair or maintenance work.

| Characteristics | Image | Materials |

| The range of ACS Agitators, is formed by groups from 1,5 to 7,5 kW, and from 680 to 4160 Newton, has a reducer that generates a rotation of the propeller at low revolutions, between 36 and 63 rpm. the diameter of the propeller is between 1100 and 2500 mm. In order to select the submerged agitator, the following parameters must be taken into account:

The hydraulic part and the motor of the ACS series are joined by a common axis, protecting the motor’s watertightness, by means of a double mechanical seal system housed in a dielectric oil chamber, which lubricates and cools the mechanical seals. Shaft rectified in the base of the bearings and base of the mechanics, oversized with respect to the standard parameters of use, and dynamically balanced. No lubrication required. |  |

|

- Pumping stations and recirculation of active sludge in wastewater treatment plants, in nitrification and denitrification processes.

- Sludge storage and digestion

- Biological reactors activated sludge.

- Homogenisation tanks.

- Biogas plants.

- Pumping of slurry.

- Washing of sand filters.

- Industrial processes in textile, paper, food, ceramic products, etc.

- Wastewater treatment plants.

- Pumping of municipal and industrial wastewater.

- Storm tank.