1. Application of chlorine gas

Chlorine is a yellow-green gas with a strong odor and is very toxic to humans and the surrounding environment. Chlorine gas is widely used in water supply plants to disinfect water before it is supplied to the water supply network.

Chlorine gas is a toxic gas. If humans inhale a small amount of chlorine gas, it can strongly irritate the respiratory tract and corneal mucosa, and can even cause suffocation and death.

Because chlorine gas is a very toxic gas, it is necessary to have labor safety measures.

In water and wastewater treatment plants, chlorine (Cl₂) is used to disinfect water, but chlorine leaks can occur from chlorine filling systems, valves, tanks, or pipes. To ensure safety for workers and the environment, chlorine neutralization towers are used to treat leaked chlorine gas before being discharged.

2. Operating principle of the leaking chlorine gas neutralization tower

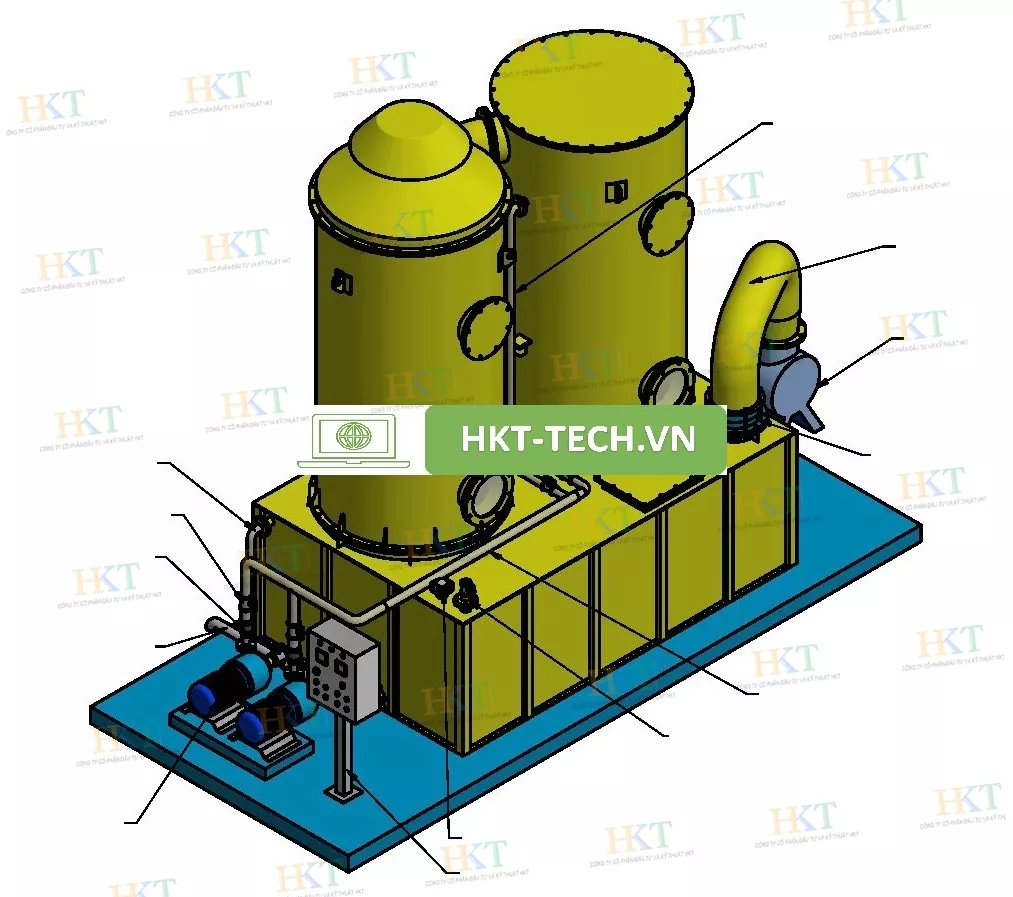

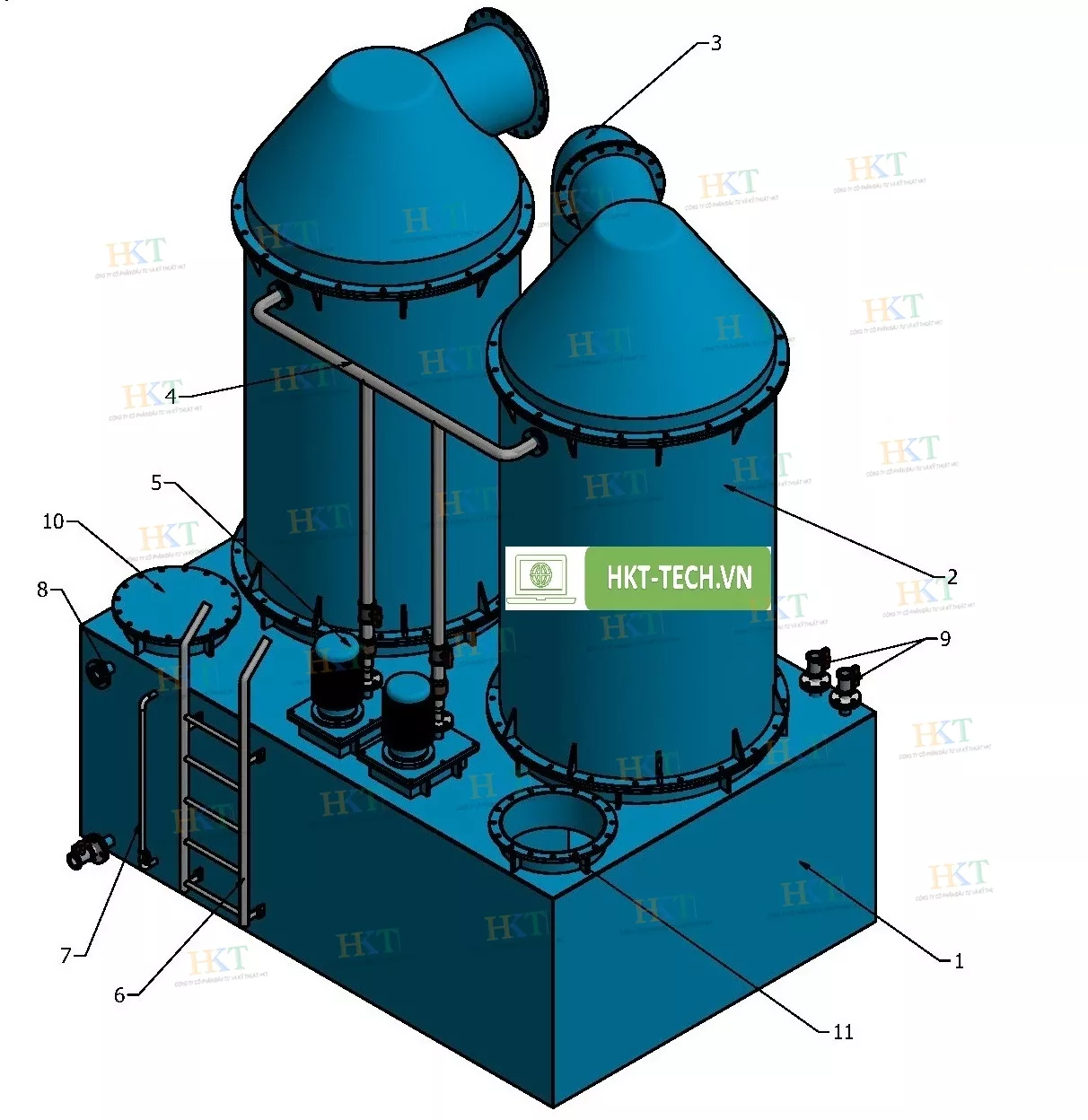

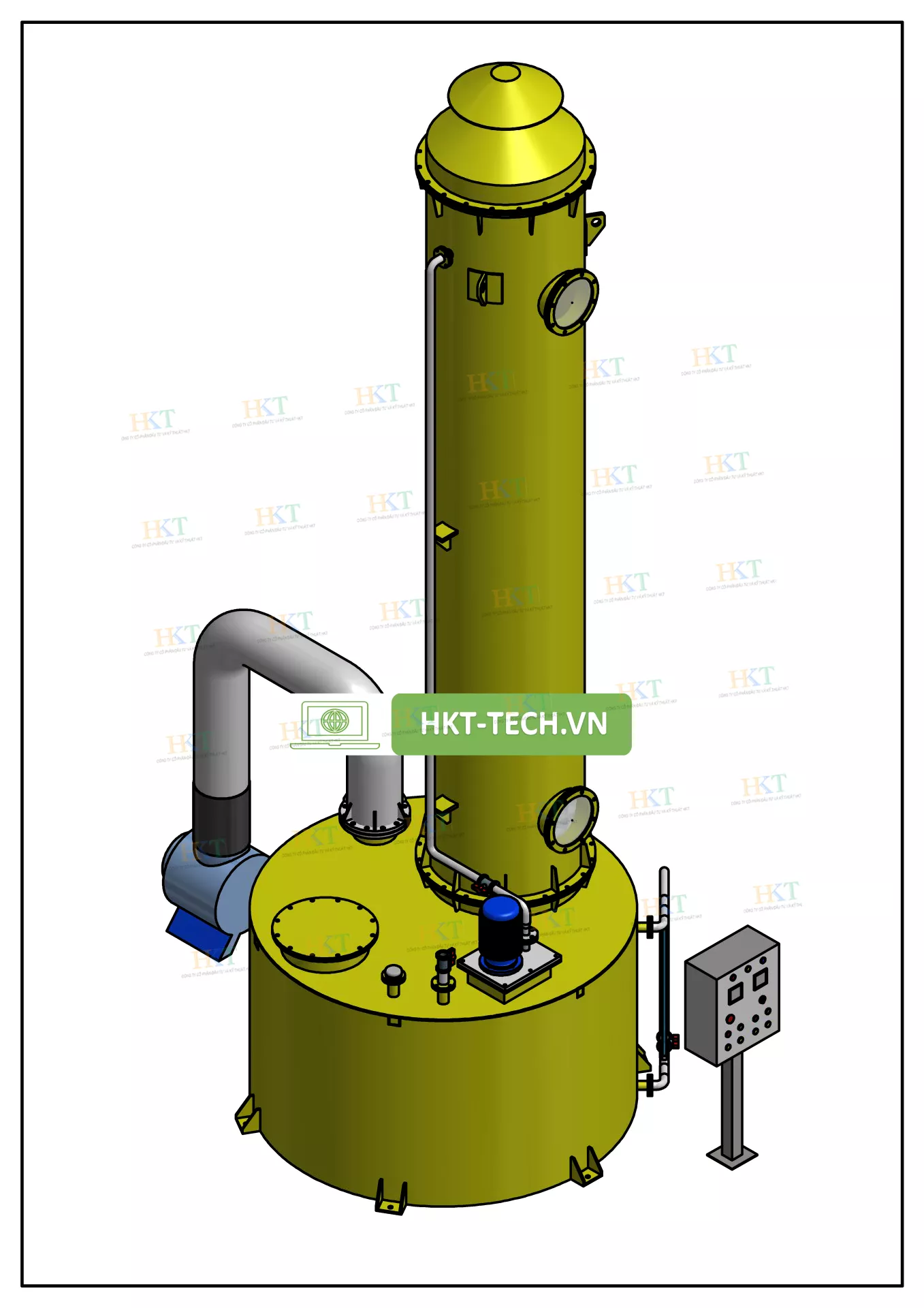

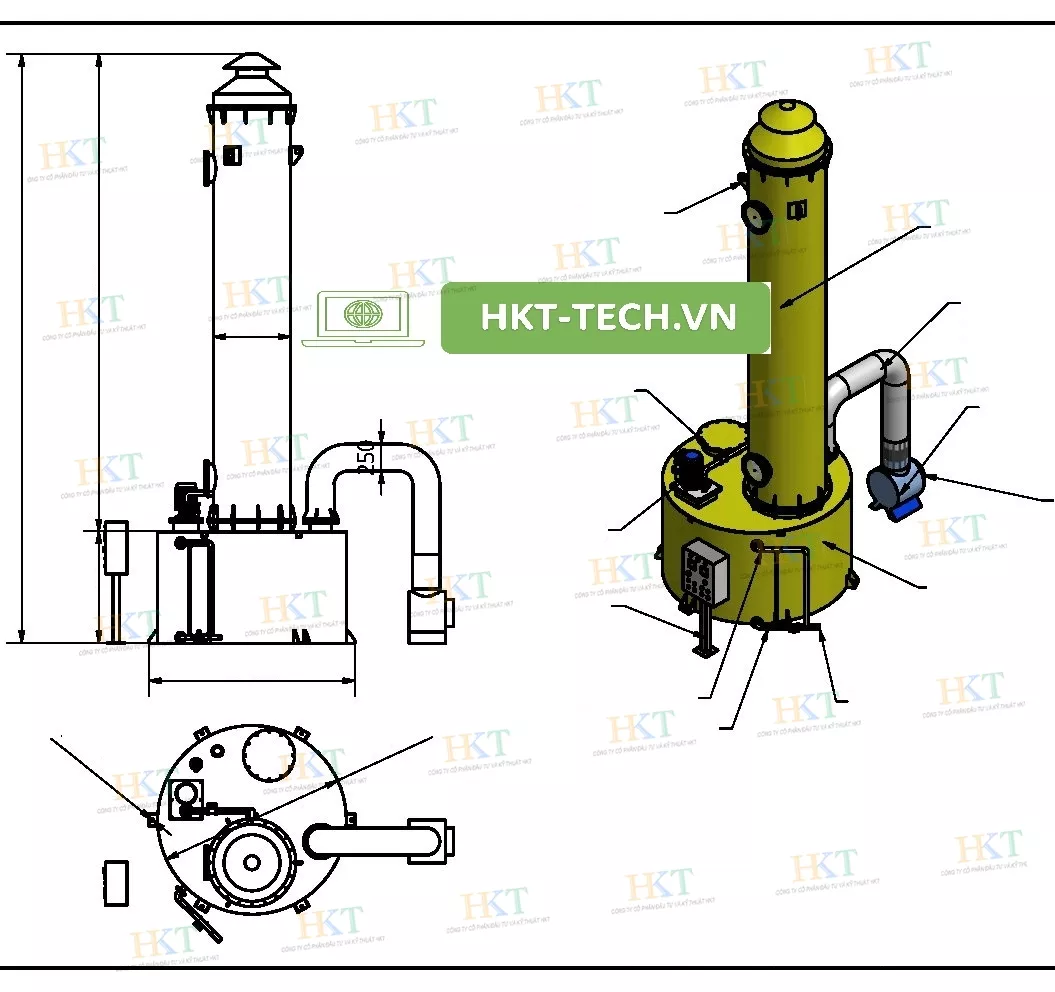

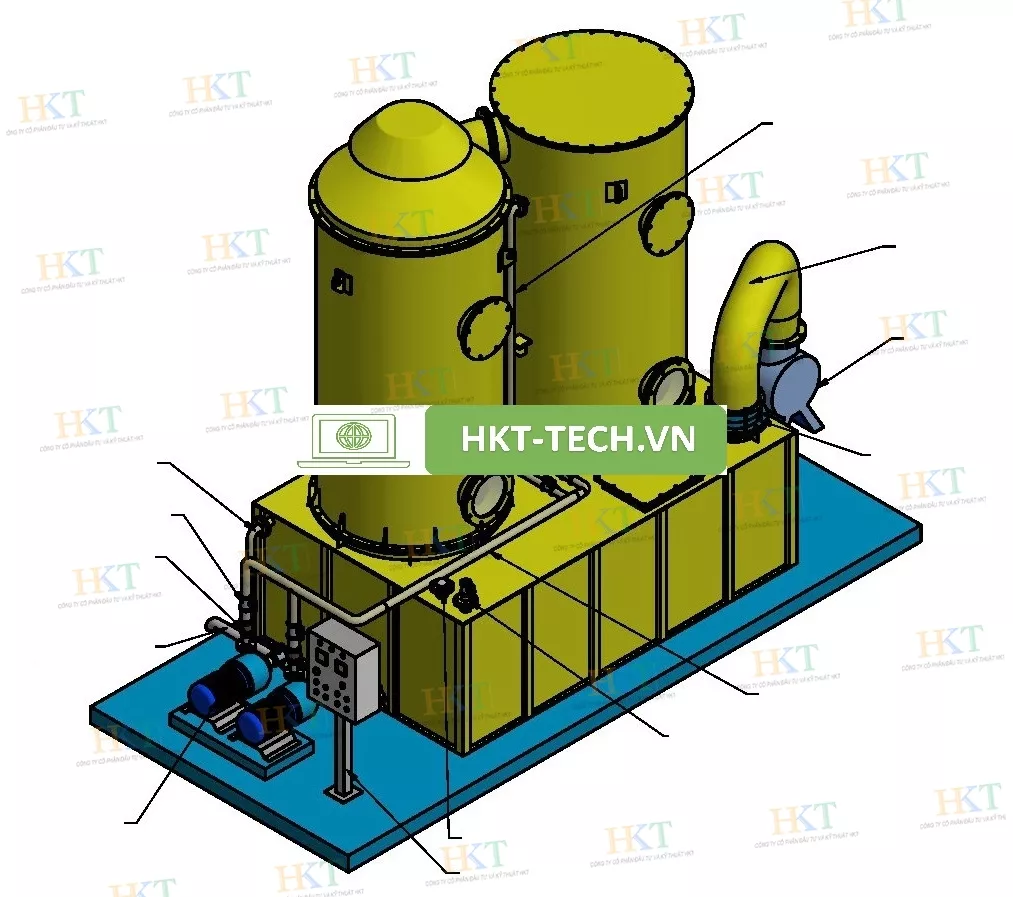

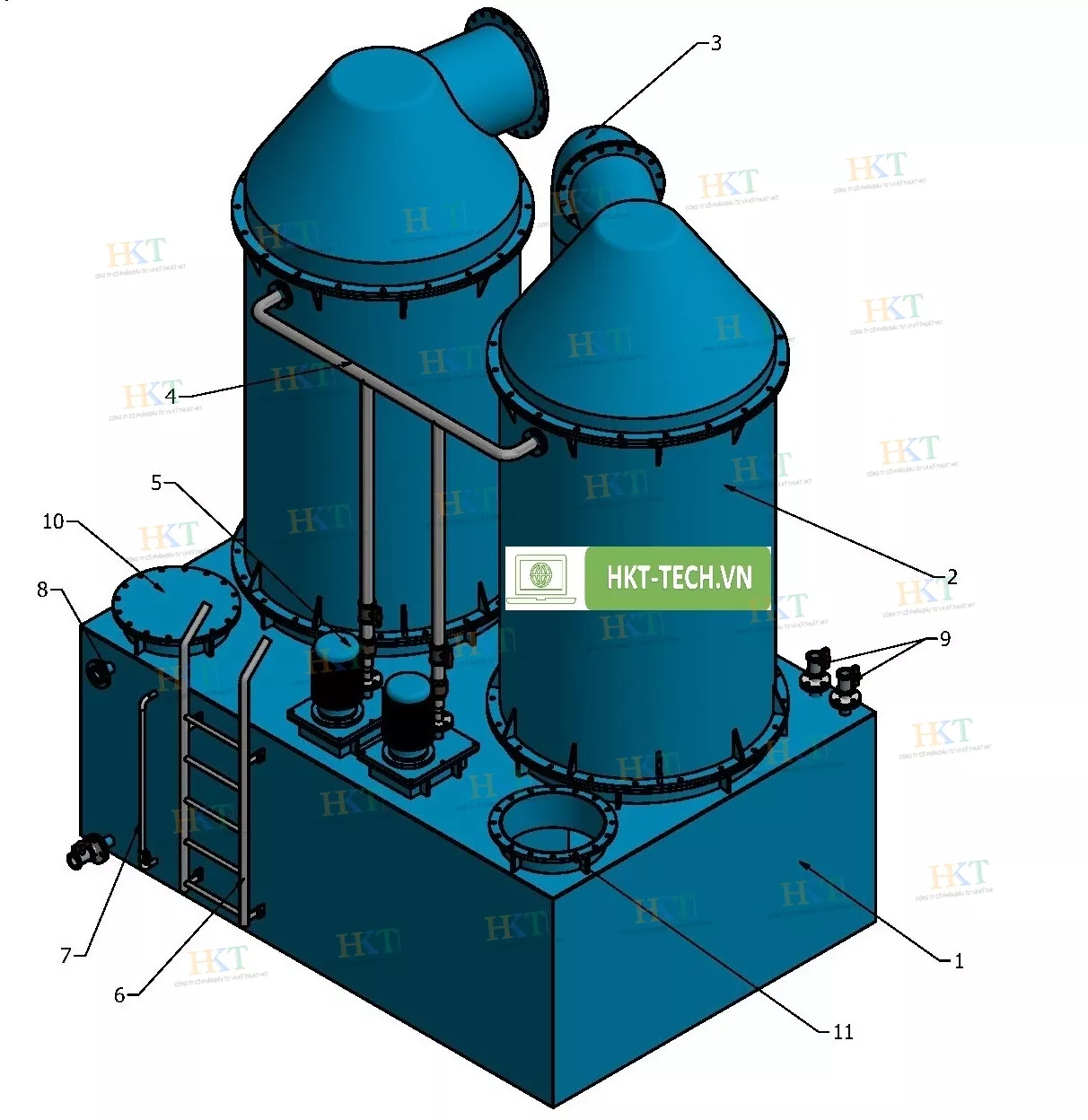

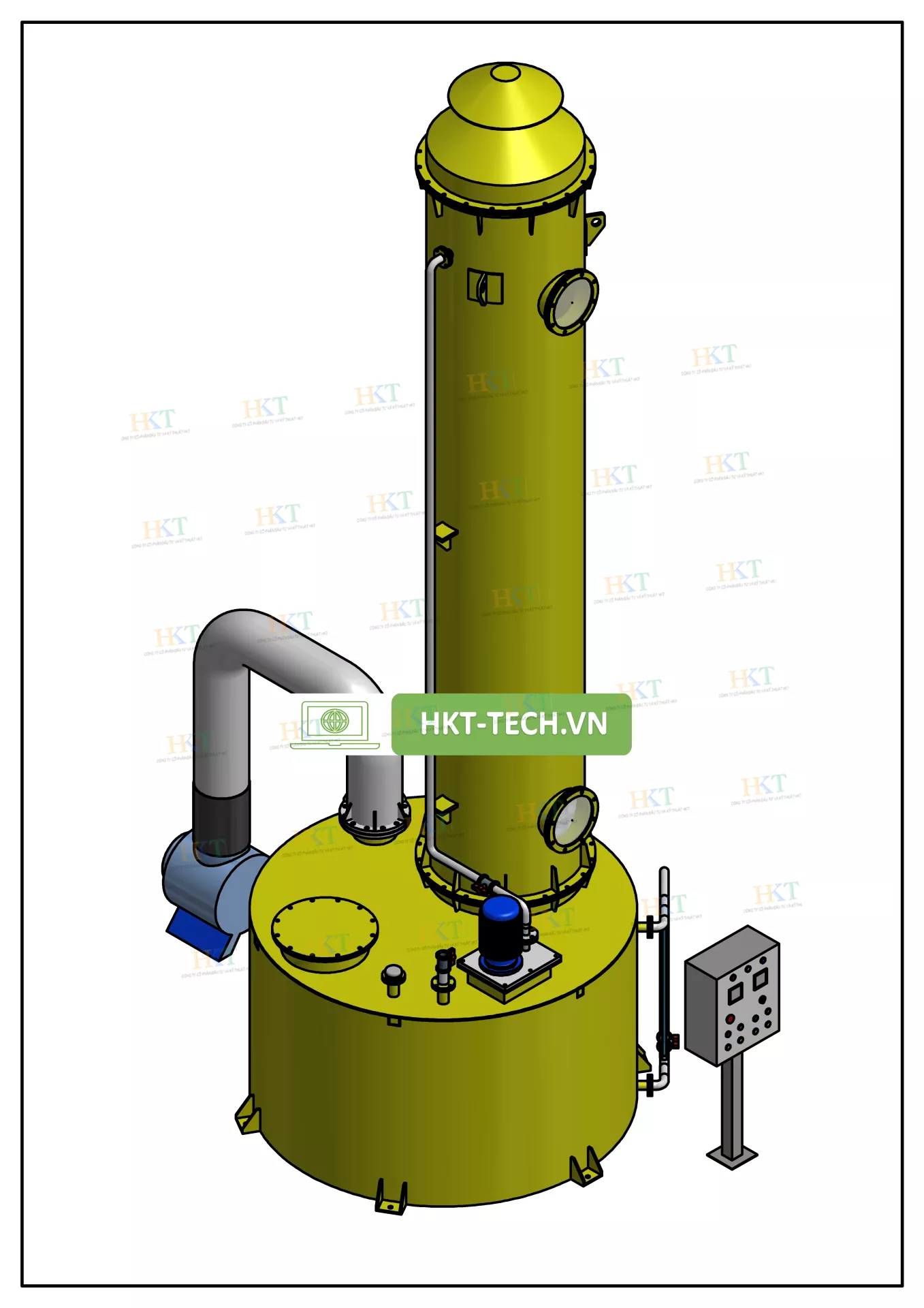

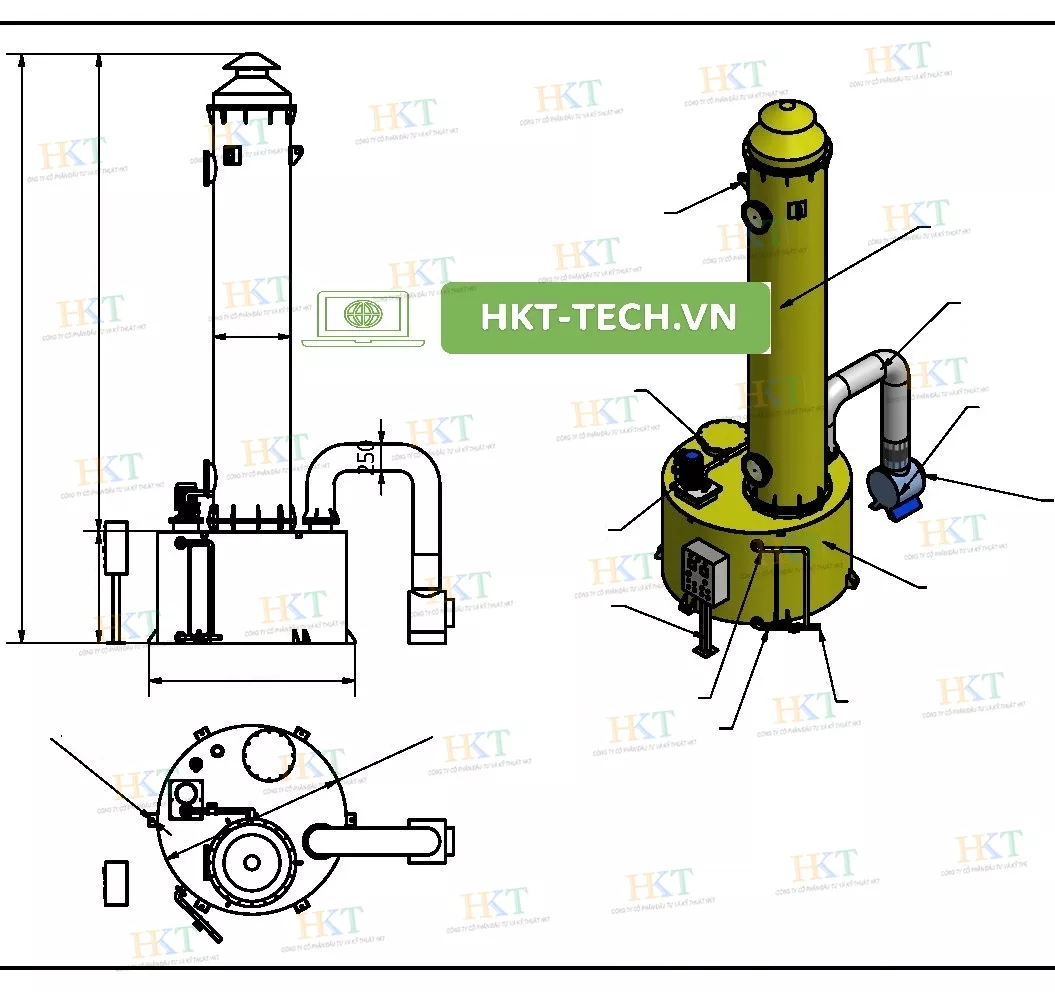

Leaking chlorine neutralization tower system includes:

– The tank contains a chemical mixture of 20% NaOH, NaCL, NaOCL and a chlorine gas neutralization tower. Tower shell material structure: Composite, PP, SS400 composite coated to prevent corrosion.

– Sensor to detect chlorine gas leaks, including signaling devices: horn and lights

– Leaking chlorine exhaust fan meets treatment capacity of up to 10,000m3/h

– Pump chemical mixture of NaOH 20%, NaCL, NaOCL

– Electrical cabinet with fully automatic control or manual operation (not recommended because chlorine is an extremely toxic gas)

– Pipes and valves connecting the system are made of chemically resistant materials

The system's operating sequence is completely automatic and takes place as follows:

– When there is a chlorine gas leak in the air (in the chlorine room), the chlorine leak detection sensor will record the measured value and send it to the central processing unit. Here the returned value will be compared with the operator's set value (Normally the set value is from 0.1 - 1.5 ppm). If the set threshold is exceeded, the central processor will send a signal to the system's control cabinet.

– The electrical cabinet control system, when receiving a signal from the central processor, will close the next points to activate the paint layer of neutralization compound NaOH 20%, NaCL, NaOCL. The horn and electric light are turned on at the same time to warn, the fan will run after a set time, usually 5 to 10 seconds to pump and support the appropriate chemical fluid.

– The process of absorbing chlorine and neutralizing chlorine gas with NaOH solution occurs continuously until the leakage content in the air (in the chlorine house) drops below the setting.

– The chlorine gas is removed, at this time the central processor will send an electrical signal to the control cabinet to open the contacts for the leaking chlorine suction fan, pump the neutralizing chemical NaOH (20%), the buzzer and alarm lights turn off. The process of handling the leak problem is now over. The operating staff continues to bring protection (clothes, masks, etc.) to enter the Chlorine room to troubleshoot and repair the problems that have damaged the equipment.

– After each time the system operates as above, the amount of NaOH solution must be completely replaced to serve the working cycle when a new problem occurs.

3. Application of Chlorine Neutralization Tower

- Chemical factories, paper factories: Treatment of chlorine gas generated during production.

- Water supply & wastewater treatment station: Treat chlorine leaks from the disinfection system.

- Storing and transporting chlorine: Ensure safety when storing or refilling chlorine.

- Laboratories, hospitals: Handling chlorine gas in chemical research.

4. Benefits of Using Chlorine Neutralization Tower

- Environmental protection: Minimize the risk of toxic gas pollution.

- Labor safety: Limiting the harmful effects of chlorine gas on humans.

- High treatment efficiency: Remove up to 99% of leaked chlorine gas.

- Low operating costs: Uses common chemicals, easy to maintain.